Saule company is developing solar cells exploiting hybrid organic–inorganic materials with perovskite structures, typically alkylammonium lead halides, as the active layer converting sunlight to electricity.

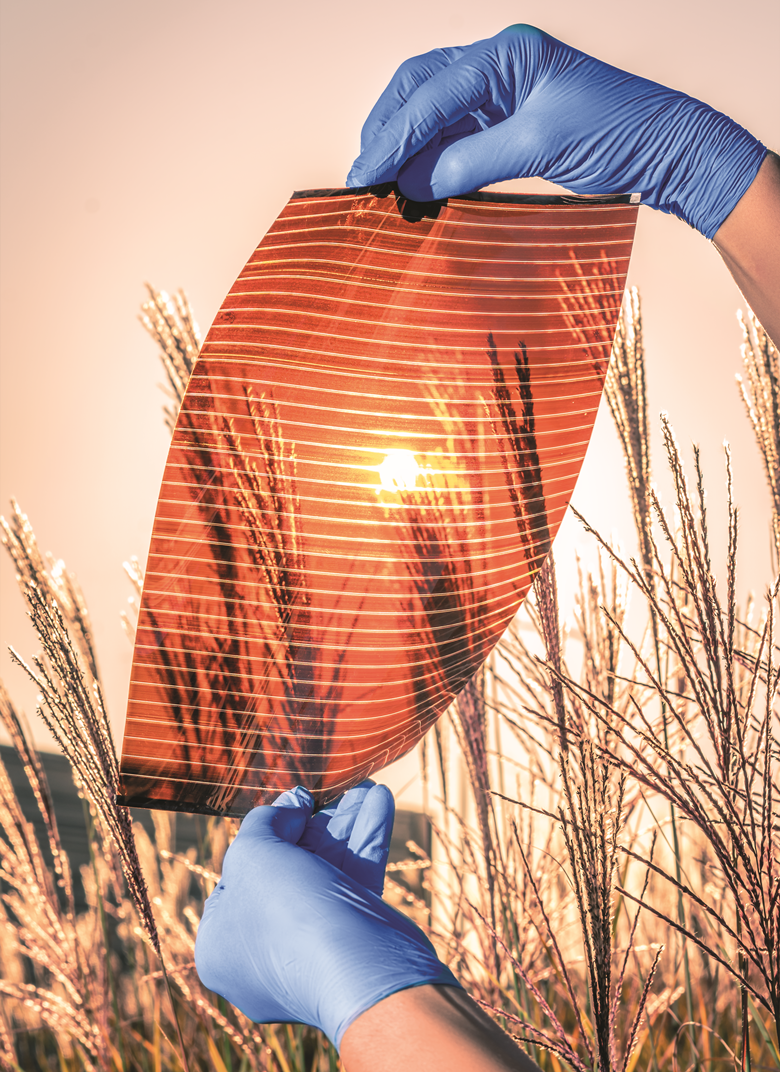

Saule is unusual in its focus on extremely thin cells that can be flexible, although this prototype is not, and very lightweight, at just 500g/m2. it be able to produce such thin cells in a way that could scale up to mass production Saule uses ink-jet printing.

Its chemists formulate inks so that every layer of different material in the cell has the right properties to produce and transport electrons when light is shone on them. They have also optimised parameters for printing, and then drying and heating the thin films so that the materials crystallise.

{Stability not a bogeyman}

it has been using industrial print heads from the beginning of our R&D work, which allowed us to establish printing specifications which could be directly transferred to the industrial manufacturing facility.’

Saule company intends to work towards making its BIPV modules transparent so that they can replace windows, applying coatings as pixels with gaps for light to pass through in between. While this means the modules can generate less power in total, it enables solar power to be deployed in new places.

Perhaps perovskite solar cells’ major weakness is a lack of stability, with the hybrid organic-inorganic material prone to degradation by water.

{This prototype is the very first perovskite-based building integrated photovoltaic product demonstration}

Berry does see stability as a key challenge for perovskites, but stresses that it should be seen in context. ‘The challenge of stability is not exclusive to perovskites,’ he underlines. Berry says the issue is ‘more a statement of how quickly they’ve become efficient than it is to say stability is this big bogeyman for the technology’.

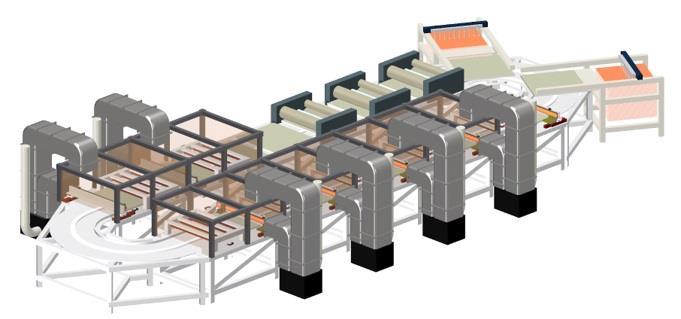

Saule’s next step is launching a fully-automated pilot production line for making large perovskite modules, The company then hopes to work with different industrial partners to develop products based on flexible perovskite PV technology, such as putting them on cars, industrial rooftops and small electronic devices.

{Perovskite-silicon solar cell achieves 28% efficiency}

UK-headquartered Oxford PV has improved its method for coating a hybrid organic–inorganic perovskite-based layer on top of a traditional silicon solar cell to attain a new efficiency record. Using this ‘tandem’ approach the company produced a 28% conversion efficiency, 1cm2 cell, certified by the US National Renewable Energy Laboratory.

We are continuing to push our perovskite-silicon solar cell technology, with a roadmap that extends beyond 30% efficiency,’ saule says ‘The solar cells we are developing are not only efficient but also stable.’

Oxford PV uses the tandem approach to enhance efficiency of existing solar panel technologies, rather than to compete against them. The company is already producing 300mm x 300mm cells at a thin-film development line facility in Brandenburg, Germany, which it purchased from electronics and engineering giant Bosch in 2016.

‘Our pilot line is routinely producing commercial sized tandem solar cells for validation by our development partner – a major manufacturer of silicon solar cells and modules,’ says Frank Averdung, Oxford PV’s chief executive officer. ‘With new collaborations with key industry players strengthening our manufacturing capabilities, the foundations are in place to move perovskite photovoltaics into commercial phase.’

Comments

Post a Comment